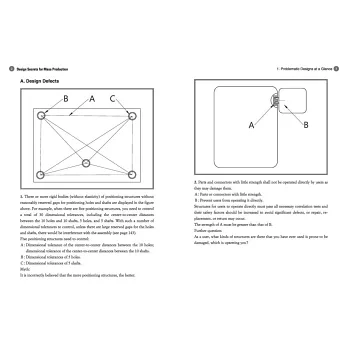

1. Problematic Designs at a Glance 1

A. Design Defects 2

B. Manufacturing Considerations 14

C. Management Issues 15

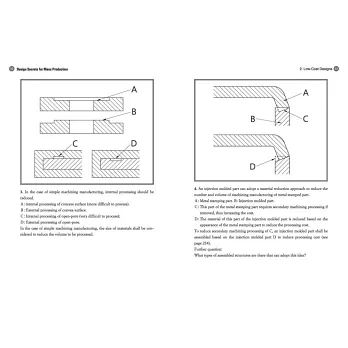

2. Low-Cost Designs 17

A. Design Strategies 18

B. Manufacturing Choices 28

C. Management Considerations 43

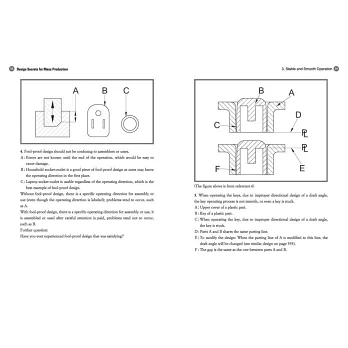

3. Stable and Smooth Operation 49

A. Exploration of Principles 50

B. Examples 54

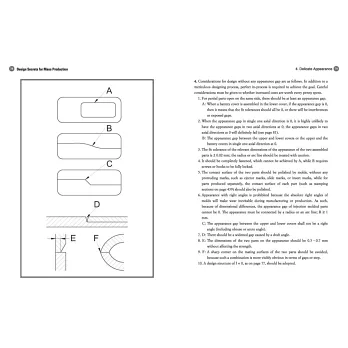

4. Delicate Appearance 63

A. Industrial Design Problems and Improvements 64

B. Control of Appearance Gaps and Steps 73

C. Delicate Appearance and Operation 93

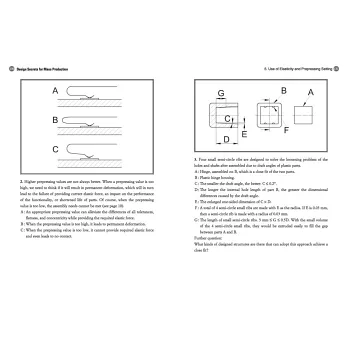

5. Use of Elasticity and Prepressing Setting 105

A. Principles and Classifications 106

B. Examples 123

C. Prepressing Setting 128

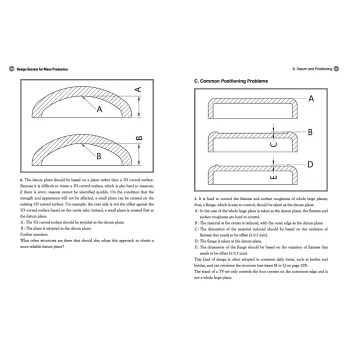

6. Datum and Positioning 141

A. Essentials and Plane Positioning 142

B. Height Positioning 155

C. Common Positioning Problems 161

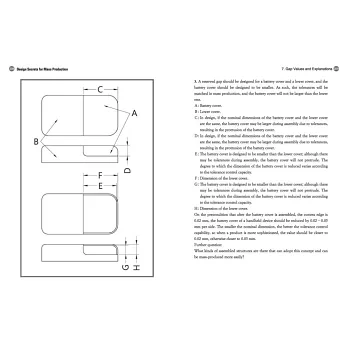

7. Gap Values and Explanations 185

A. Principles and Empirical Value of Reserved Gaps 186

B. Improvement Measures 206

8. Impacts of Deviation enlargement 225

A. Definitions 226

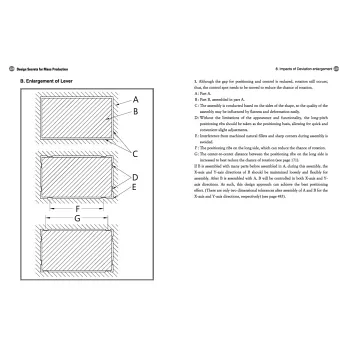

B. Enlargement of Lever 228

C. Enlargement of Rotation 233

D. Enlargement of Skewness 235

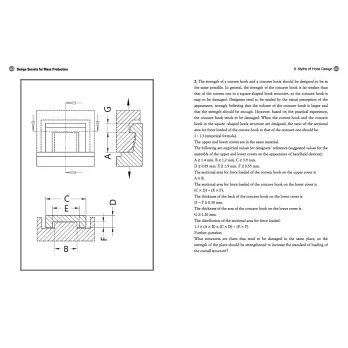

9. Myths of Hook Design 245

A. Definitions 246

B. Principles 251

C. Design Thinking 260

D. Troubleshooting 279

10. Screw Application 289

11. Methods of Increasing Strength 305

A. Basic Reinforcing Methods 306

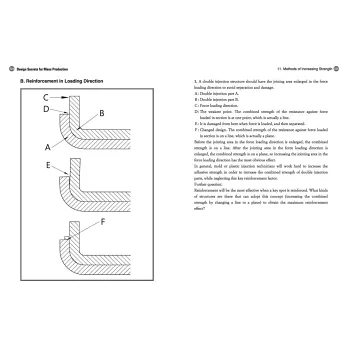

B. Reinforcement in Loading Direction 324

C. Strengthening of Adhesion of Tape 339

D. Impact Protection 348

12. Important 2D Assembly Sectional Views 355

A. Purpose and Methods 356

B. Guidelines 358

C. 2D Drawing Improvements 363

13. Simulation 369

A. Overview 370

B. Drawing-based Simulation 372

C. Mock-up-based Simulation 380

D. Case Study 383

14. Designs that are Hard to Control 387

A. Effective Designs 388

B. Assembly Reliability 398

C. Blind Spots in Design 402

D. Test Improvement 410

15. Differences between Mock-Ups and Tooling Parts 413

A. Changes of Thinking 414

B. Manufacturing Issues and Know-How of Tooling Parts 423

16. Rounds, Chamfers, and Sharp Corners 445

A. Machined Natural Fillets and Sharp Corners 446

B. Rounds 450

C. Chamfers 456

17. 6σ Design and Tolerance Analysis 459

A. Introduction 460

B. Meaning and Attitude 463

C. Design Methods and Examples 465

D. Pitfalls and Challenges 495

18. Process Capability Improvement of Factories 501

A. Design Requirements 502

B. Process Improvement of Suppliers 505

19. Parting Line 509

A. Examination of Principles 510

B. Better Choices 514

20. Technology Management 529

A. Supervisor Functions 530

B. Talent and Organization Management 541

C. Shortening of Research and Development Time 550

D. Enhancement of Design Effects 557

21. Interaction with Readers Q&A and Case Study 570

References 589

天天爆殺

天天爆殺  今日66折

今日66折

博客來

博客來 博客來

博客來 博客來

博客來 博客來

博客來 博客來

博客來